Most boaters agree with the simple but truthful adage: “Keep the water out of the boat, keep the boat off the bottom, and everything else can be worked out.” Unfortunately, many boaters neglect an essential way of maintaining this condition— properly working bilge pumps. Bilge pumps are a necessity aboard a boat, yet they often get the least attention. It doesn’t help that they can be located in the deepest darkest places.

A controlled amount of sea water is allowed through the hull of the average boat for numerous reasons, from cooling engines and equipment to stuffing boxes on propeller shafts and rudder posts. For these reasons, boaters have accepted some water in the bilge. Bilge pumps are installed at the lowest point to clear excess water that accumulates, so it’s not uncommon to install cycle clocks to monitor how frequently the bilge pumps come on. If they come on with increased frequency, that would indicate a problem worthy of attention.

Just the word “bilge” has a negative connotation, and for good reason. It’s often a smelly cocktail of more than just water, including oil, coolant and a variety of living organisms. It’s understandable why boaters tend to avoid the bilge areas.

First Things First

Clean and dry the bilge area regularly, and you reap a range of benefits. Hazardous liquids won’t get pumped overboard, and you reduce odors from emanating into the rest of the boat. And it helps in finding sources of leaking water or fluids. Don’t assume the bilge has to be wet. As construction methods and components have improved, it’s not a given anymore that water will be present in the bilge. Dripless seals have largely replaced traditional stuffing boxes, eliminating one of the most common sources of bilge water.

If your boat’s air-conditioning condensate drains into the bilge, consider capturing it in a sump box and pumping it overboard. Make sure under-engine areas are sealed catch basins preventing engine fluids from being pumped overboard. Line under-engine areas with absorbent pads. This not only helps to contain leaks, it may also help you find a leak by containing the drip directly under source. With a little effort, you can maintain a clean and possibly dry bilge.

Keep pathways open. Limber holes are drain holes through the framing or other structural members of a boat. They prevent water from being trapped and allow water to pass through to the lowest point where the pumps are located. On new and old boats alike, debris consisting of screws, wire ties or other construction materials can fall into the low points throughout the boat, possibly blocking the limber holes and preventing water from reaching the pump.

Even if the debris doesn’t block the opening, it can be washed toward the pump. One of the most frequent points of failure in bilge pumps is ingesting foreign objects.

Double Duty

Over the years, bilge pumps have evolved in the minds of many boat manufacturers and boaters to also serve as emergency pumps for a component failure or breach in the hull’s watertight integrity.

There are enough holes through the average boat’s hull to sink it quickly, but we control these openings with valves to allow the water to pass in a controlled manner. Unfortunately, through-hull fittings and associated connections are neglected as well. Boat flooding due to poorly maintained through-hull components are consistently a leading cause of insurance claims.

Even on a new boat, don’t assume the manufacturer has sized the bilge pump to handle all the water that could enter an area. A surprisingly large amount of water will enter through the smallest of holes. Aided by pressure, a half-inch hole at only 1 foot below the waterline allows about five gallons of water per minute into the hull. Increase that to a 1-inch hole at 4 feet below the waterline, and you can expect seawater to enter at an astonishing rate of nearly 40 gallons per minute. Regrettably, many bilge pumps are undersized to perform as emergency pumps. A prudent boater installs or carries a portable high-volume de-watering pump for emergencies.

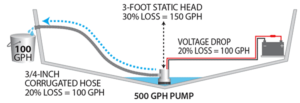

When adding or replacing a bilge pump, don’t forget to factor static head pressure into the equation. A pump’s capacity is reduced by a factor related to how high the pump must lift the water above the level of the pump.

Power to the Pump

Bilge pumps on most recreational boats have some type of water sensing switch activating the pump when water reaches a certain level around it. These require equal attention, as failures can also occur in the switch, and no power means no pumping. Switches can be a float style, with water lifting the switch to activate the pump, or they can be water sensing by electrical conductance. Inspect your boat’s float style switches to be certain nothing interferes with lifting the mechanism. For switches that use electrical contacts, be sure contacts remain clean and free of corrosion.

Inspection Is Perfection

Smart boaters keep bilges clean. Inspect regularly for the following items.

• It’s best to maintain a completely dry bilge, but if not, monitor the amounts of water and be sure to know the water’s source.

• Clean the area to stay free of scum or microbial growth.

• Look for corrosion and rust.

• Inspect wiring and electrical connections on pumps and switches.

• Activate the switch to ensure it turns on the pump automatically.

• Be certain lights or alarms at the helm are working and notifying you of a bilge pump on high water.

• Exercise seacocks to be certain they can open and close.